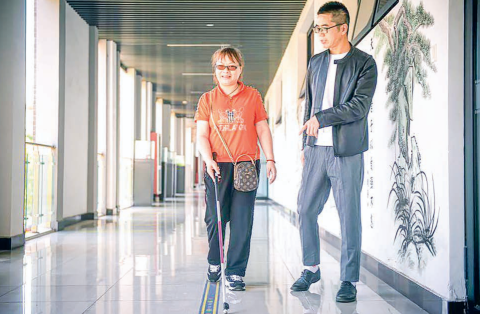

CHINA is exploring the use of advanced technologies such as smart bionic hands and guide robots to improve the well-being of people with disabilities, ensuring that scientific and technological progress benefits this community, an official said Tuesday.

Zhou Changkui, chairperson of the Board of Executive Directors of the China Disabled Persons’ Federation, said at a press conference that these applications were unveiled at a recent forum.

CHINA is exploring the use of advanced technologies such as smart bionic hands and guide robots to improve the well-being of people with disabilities, ensuring that scientific and technological progress benefits this community, an official said Tuesday.

Zhou Changkui, chairperson of the Board of Executive Directors of the China Disabled Persons’ Federation, said at a press conference that these applications were unveiled at a recent forum.

He added that China will further focus on the development of new technologies and industries, including brain-computer interfaces, to better support people with disabilities.

According to Zhou, the federation and some other governmental departments have jointly issued a guiding document to promote the use of technology in supporting people with disabilities. It is also collaborating with universities, research institutes and high-tech companies to boost the development of relevant technologies and industries.

Zhou noted that during the upcoming 15th Five-Year Plan period (2026-2030), China will continue to promote the application of artificial intelligence and other cutting-edge technologies to serve people with disabilities, and ensure that advanced technologies better meet their needs. — Xinhua

GNLM

CHINA is exploring the use of advanced technologies such as smart bionic hands and guide robots to improve the well-being of people with disabilities, ensuring that scientific and technological progress benefits this community, an official said Tuesday.

Zhou Changkui, chairperson of the Board of Executive Directors of the China Disabled Persons’ Federation, said at a press conference that these applications were unveiled at a recent forum.

He added that China will further focus on the development of new technologies and industries, including brain-computer interfaces, to better support people with disabilities.

According to Zhou, the federation and some other governmental departments have jointly issued a guiding document to promote the use of technology in supporting people with disabilities. It is also collaborating with universities, research institutes and high-tech companies to boost the development of relevant technologies and industries.

Zhou noted that during the upcoming 15th Five-Year Plan period (2026-2030), China will continue to promote the application of artificial intelligence and other cutting-edge technologies to serve people with disabilities, and ensure that advanced technologies better meet their needs. — Xinhua

GNLM

Nissan Motor is developing technology with Waseda University to recycle rare earth metals from magnets in scrapped electric vehicle motors.

The project has taken on a new urgency since China announced in April it will restrict exports of rare earths. The process involves melting the motor in an electric furnace with other chemicals to separate off the rare earths. The metals are essential to manufacturing EVs.

Nissan Motor is developing technology with Waseda University to recycle rare earth metals from magnets in scrapped electric vehicle motors.

The project has taken on a new urgency since China announced in April it will restrict exports of rare earths. The process involves melting the motor in an electric furnace with other chemicals to separate off the rare earths. The metals are essential to manufacturing EVs.

Nissan Motor Senior Engineer Ogawa Kazuhiro says the technical challenge is to increase the amount of rare earths they can recycle from the magnets. "We hope to have the system in practical use for when more scrapped electric motors are available," he said. "That is expected to be around 2030."

Toyota Motor is also testing a technology to recycle rare earths from hybrid car motors.

Ref : NHK

Nissan Motor is developing technology with Waseda University to recycle rare earth metals from magnets in scrapped electric vehicle motors.

The project has taken on a new urgency since China announced in April it will restrict exports of rare earths. The process involves melting the motor in an electric furnace with other chemicals to separate off the rare earths. The metals are essential to manufacturing EVs.

Nissan Motor Senior Engineer Ogawa Kazuhiro says the technical challenge is to increase the amount of rare earths they can recycle from the magnets. "We hope to have the system in practical use for when more scrapped electric motors are available," he said. "That is expected to be around 2030."

Toyota Motor is also testing a technology to recycle rare earths from hybrid car motors.

Ref : NHK

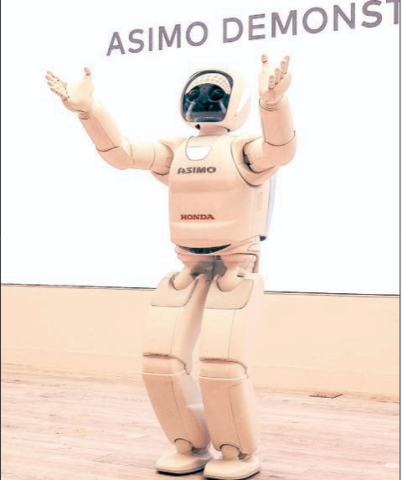

JAPANESE electronics maker Murata Manufacturing Co., Waseda University and two other companies teamed up to develop hu- manoid search and rescue robots as part of a wider effort to revive Japan’s formerly world-leading robotics sector.

The four entities, including Kyoto-based robot maker Tmsuk Co and technology service company Sre Holdings Corp in Tokyo, said in late June that they plan to develop a robot with all Japan-made components, such as sensors and precision instruments.

JAPANESE electronics maker Murata Manufacturing Co., Waseda University and two other companies teamed up to develop hu- manoid search and rescue robots as part of a wider effort to revive Japan’s formerly world-leading robotics sector.

The four entities, including Kyoto-based robot maker Tmsuk Co and technology service company Sre Holdings Corp in Tokyo, said in late June that they plan to develop a robot with all Japan-made components, such as sensors and precision instruments.

The robot is designed to stand 3 metres tall, weigh 300 kilogrammes, walk at around 5 kilometres per hour and lift 100 kg or more. Given its demographic challenges, the companies believe disaster-prone Japan needs to develop such rescue robots.

“We want to build a robot that is much stronger than a human and can move rubble,” Tmsuk Chairman Yoichi Takamoto said at a press conference in late June.

Japan was once a global leader in humanoid robotics, with Waseda University having developed the world’s first full-scale bipedal robot, WABOT-1, in 1973. Honda Motor Co led humanoid robotics technology with ASIMO, whose final model was released in 2011. Hoping to play catchup with US and Chinese manufacturers, the four partners aim to develop a pilot model by the end of 2026 and a mass-production version by March 2029, they said. — Kyodo

GNLM

JAPANESE electronics maker Murata Manufacturing Co., Waseda University and two other companies teamed up to develop hu- manoid search and rescue robots as part of a wider effort to revive Japan’s formerly world-leading robotics sector.

The four entities, including Kyoto-based robot maker Tmsuk Co and technology service company Sre Holdings Corp in Tokyo, said in late June that they plan to develop a robot with all Japan-made components, such as sensors and precision instruments.

The robot is designed to stand 3 metres tall, weigh 300 kilogrammes, walk at around 5 kilometres per hour and lift 100 kg or more. Given its demographic challenges, the companies believe disaster-prone Japan needs to develop such rescue robots.

“We want to build a robot that is much stronger than a human and can move rubble,” Tmsuk Chairman Yoichi Takamoto said at a press conference in late June.

Japan was once a global leader in humanoid robotics, with Waseda University having developed the world’s first full-scale bipedal robot, WABOT-1, in 1973. Honda Motor Co led humanoid robotics technology with ASIMO, whose final model was released in 2011. Hoping to play catchup with US and Chinese manufacturers, the four partners aim to develop a pilot model by the end of 2026 and a mass-production version by March 2029, they said. — Kyodo

GNLM

A UK-based firm is aiming to launch a piloted flying taxi (VX4) in 2028, powered by electricity, that it says will operate at a similar price point to the country's well-known black cabs.

A UK-based firm is aiming to launch a piloted flying taxi (VX4) in 2028, powered by electricity, that it says will operate at a similar price point to the country's well-known black cabs.

Simon Davies, Chief Test Pilot, Vertical Aerospace said "All the signs are that there's an incredible demand for these aircraft, for the capability it brings. We've got over 1,500 orders and options for our aircraft already from customers all around the world in five different regulatory jurisdictions, so America, Brazil, Europe, Japan."

The VX4 will be used by operators as a flying taxi, and it's going to allow people to avoid traffic jams and do that at a price that's very similar to that of a black taxi."

mitv

A UK-based firm is aiming to launch a piloted flying taxi (VX4) in 2028, powered by electricity, that it says will operate at a similar price point to the country's well-known black cabs.

Simon Davies, Chief Test Pilot, Vertical Aerospace said "All the signs are that there's an incredible demand for these aircraft, for the capability it brings. We've got over 1,500 orders and options for our aircraft already from customers all around the world in five different regulatory jurisdictions, so America, Brazil, Europe, Japan."

The VX4 will be used by operators as a flying taxi, and it's going to allow people to avoid traffic jams and do that at a price that's very similar to that of a black taxi."

mitv

The Ax-4 crew, launched on June 25, from NASA's Kennedy Space Center, has concluded their mission on the International Space Station (ISS) after 250+ orbits of Earth and covering over six million miles.

The Ax-4 crew, launched on June 25, from NASA's Kennedy Space Center, has concluded their mission on the International Space Station (ISS) after 250+ orbits of Earth and covering over six million miles.

A special farewell ceremony marked the conclusion of the mission, where Group Captain Shubhanshu Shukla became the first Indian astronaut on the ISS to bid farewell to space. Their return brings home a successful chapter in international space collaboration with India. The return journey after 18 days, concluded their mission with a splashdown on July 15th.

mitv

The Ax-4 crew, launched on June 25, from NASA's Kennedy Space Center, has concluded their mission on the International Space Station (ISS) after 250+ orbits of Earth and covering over six million miles.

A special farewell ceremony marked the conclusion of the mission, where Group Captain Shubhanshu Shukla became the first Indian astronaut on the ISS to bid farewell to space. Their return brings home a successful chapter in international space collaboration with India. The return journey after 18 days, concluded their mission with a splashdown on July 15th.

mitv

Chairman of the State Administration Council, Commander-in-Chief of Defence Services Senior General Min Aung Hlaing, accompanied by senior Tatmadaw officers from the Office of the Commander-in-Chief, the commander of Central Command and officials, inspected Tatmadaw Leather Factory (Meiktila) in Meiktila Station yesterday.

Chairman of the State Administration Council, Commander-in-Chief of Defence Services Senior General Min Aung Hlaing, accompanied by senior Tatmadaw officers from the Office of the Commander-in-Chief, the commander of Central Command and officials, inspected Tatmadaw Leather Factory (Meiktila) in Meiktila Station yesterday.

The factory manager reported to the Senior General on the accomplishment of the guidance given by the Senior General on his inspection tour in 2019, a brief history of the factory, production capacity of the factory, production of chrome leather, sole leather and goat leather per year, production techniques, and welfare for employees.

In his guidance, the Senior General said that Tatmadaw manages the distribution of clothes and equipment produced by Tatmadaw factories for the convenience of Tatmadaw members, similar to governments of the international community.

He continued that Tatmadaw is producing quality products for the clothes of all Tatmadaw members. In this regard, he added that not only raw materials but also products must be qualified.

The Senior General stressed that Tatmadaw Leather Factory (Meiktila) must strive to produce higher quality leather materials without being satisfied with the current level of products.

He emphasized that the factory needs to supply raw leather materials to Tatmadaw and private leather product factories.

As such, he noted that it is necessary to continuously study the leather production techniques of the international community.

Moreover, the Senior General underlined that efforts must be made for the production of quality raw leather materials for footwear industries as well as other industries.

The Senior General inspected the functions of relevant sections of the factory and gave necessary guidance to officials.

He viewed round raw leather material produced by the factory and presented cash awards to employees. — MNA/TTA

GNLM

Chairman of the State Administration Council, Commander-in-Chief of Defence Services Senior General Min Aung Hlaing, accompanied by senior Tatmadaw officers from the Office of the Commander-in-Chief, the commander of Central Command and officials, inspected Tatmadaw Leather Factory (Meiktila) in Meiktila Station yesterday.

The factory manager reported to the Senior General on the accomplishment of the guidance given by the Senior General on his inspection tour in 2019, a brief history of the factory, production capacity of the factory, production of chrome leather, sole leather and goat leather per year, production techniques, and welfare for employees.

In his guidance, the Senior General said that Tatmadaw manages the distribution of clothes and equipment produced by Tatmadaw factories for the convenience of Tatmadaw members, similar to governments of the international community.

He continued that Tatmadaw is producing quality products for the clothes of all Tatmadaw members. In this regard, he added that not only raw materials but also products must be qualified.

The Senior General stressed that Tatmadaw Leather Factory (Meiktila) must strive to produce higher quality leather materials without being satisfied with the current level of products.

He emphasized that the factory needs to supply raw leather materials to Tatmadaw and private leather product factories.

As such, he noted that it is necessary to continuously study the leather production techniques of the international community.

Moreover, the Senior General underlined that efforts must be made for the production of quality raw leather materials for footwear industries as well as other industries.

The Senior General inspected the functions of relevant sections of the factory and gave necessary guidance to officials.

He viewed round raw leather material produced by the factory and presented cash awards to employees. — MNA/TTA

GNLM

China sent a new test satellite into space on Thursday from the Xichang Satellite Launch Center in southwest China’s Sichuan Province. The Shiyan-28B 01 satellite was launched at 17:35 aboard a Long March-4C carrier rocket and successfully entered the preset orbit. It will be mainly used for space environment exploration and related technology tests. The launch marks the 583rd flight mission of the Long March carrier rocket series.

mitv

China sent a new test satellite into space on Thursday from the Xichang Satellite Launch Center in southwest China’s Sichuan Province. The Shiyan-28B 01 satellite was launched at 17:35 aboard a Long March-4C carrier rocket and successfully entered the preset orbit. It will be mainly used for space environment exploration and related technology tests. The launch marks the 583rd flight mission of the Long March carrier rocket series.

mitv

China sent a new test satellite into space on Thursday from the Xichang Satellite Launch Center in southwest China’s Sichuan Province. The Shiyan-28B 01 satellite was launched at 17:35 aboard a Long March-4C carrier rocket and successfully entered the preset orbit. It will be mainly used for space environment exploration and related technology tests. The launch marks the 583rd flight mission of the Long March carrier rocket series.

mitv

With China's humanoid robot industry booming, battery technology has emerged as a limiting factor in performance, prompting some tech companies to develop more advanced batteries tailored to robotic needs.

Humanoid robots are venturing into diverse areas of our lives, from transporting parts in factories and participating in marathons to playing football and even boxing in the ring.

With China's humanoid robot industry booming, battery technology has emerged as a limiting factor in performance, prompting some tech companies to develop more advanced batteries tailored to robotic needs.

Humanoid robots are venturing into diverse areas of our lives, from transporting parts in factories and participating in marathons to playing football and even boxing in the ring.

However, with a current endurance of just around two hours, humanoid robots fall significantly short of meeting the demands of more complex future tasks.

According to the Institute of Physics under the Chinese Academy of Sciences, the energy consumption of robots mainly comes from mechanical movement, especially the lifting in the vertical direction and the rapid acceleration movements.

For example, when a robot performs a backflip, it may appear effortless, but it actually demands exceptionally high battery performance. The instantaneous discharge rate required can exceed 100 times that of ordinary batteries in daily use.

An insufficient discharge rate affects the robot's performance, while a heavy battery reduces its flexibility, and low capacity limits its practical use. These issues have become significant challenges for robotics companies.

EngineAI Robotics Technology Co., Ltd., located in south China's tech hub Shenzhen, released an impressive robot dance video in March this year. In the video, the company's PM01 robot flawlessly performed the Axe Gang Dance from Stephen Chow's classic film "Kung Fu," capturing the dance's spirit with remarkable accuracy.

Zhang Nan, a hardware engineer at EngineAI, said that ternary lithium batteries are currently widely used in humanoid robots, and several existing products of EngineAI robots are also equipped with such batteries.

However, such lithium batteries have poor performance in thermal stability. With the development of humanoid robots, solid-state batteries with higher energy density, smaller size and better safety may be the future. "EngineAI is currently in contact with solid-state battery manufacturers for preliminary research," Zhang said.

X Square Robot also faces similar challenges. Wang Qian, founder of the company, said that the company's goal is to have robots take over simple and tedious physical tasks, from electronic assembly work in factories and restaurant service to everyday household chores, making general-purpose robots an indispensable part of people's lives.

The batteries currently used by X Square Robot include ternary lithium batteries and lithium iron phosphate batteries. Their common problem is the low energy density, which affects the overall endurance of the robots. For robots to enter homes and other future application scenarios with high activity levels, they need batteries with higher energy density and, most importantly, maximum safety, Wang explained.

This year's government work report outlined plans to develop future industries like embodied intelligence, highlighting the humanoid robot sector as a key focus. According to the Chinese Institute of Electronics, by 2030, the market size of China's humanoid robots is expected to reach about 870 billion yuan (about 121 billion U.S. dollars).

The swift response has come from tech companies, which are becoming the driving force behind innovation in the country. Some battery manufacturers have recognized this emerging demand and have already partnered with humanoid robot companies for research and development.

For instance, in June, battery giant CATL invested in Beijing-based Galbot, aiming to develop batteries for humanoid robots and to introduce robots into its production lines to achieve factory production automation.

BTR New Material Group, a Shenzhen-based battery supplier, in May launched the FLEX semi-solid and GUARD all-solid-state batteries tailored for humanoid robots. The company has achieved a balance between high performance and lightweight design through two major strategies: material innovation and structural optimization.

For instance, the FLEX series' high-nickel ternary cathodes use molecular-level in-situ coating technology, which can effectively increase the energy density. The GUARD series uses a lithium-rich manganese-based cathode and a lithium metal anode design, which significantly increases the energy density of the individual cell.

According to Li Zikun, director of the company's research institute, the mainstream ternary lithium batteries have shortcomings in terms of energy density, safety and stability, and high-rate discharge performance for humanoid robots. Solid-state batteries can better meet these needs.

Li believes that batteries for future humanoid robots should meet three key requirements: a balance between high energy density and safety, optimized fast charging and discharging efficiency, and stability and reliability under special working conditions.

The all-solid-state battery eliminates the risk of leakage and fire associated with traditional liquid electrolytes, providing a safety guarantee for use under extreme conditions, he said.

These high-energy-density designs can not only support the long-endurance needs of humanoid robots, but are also particularly suitable for increasing the payload in special application scenarios such as aerospace, Li added.

Xinhua

With China's humanoid robot industry booming, battery technology has emerged as a limiting factor in performance, prompting some tech companies to develop more advanced batteries tailored to robotic needs.

Humanoid robots are venturing into diverse areas of our lives, from transporting parts in factories and participating in marathons to playing football and even boxing in the ring.

However, with a current endurance of just around two hours, humanoid robots fall significantly short of meeting the demands of more complex future tasks.

According to the Institute of Physics under the Chinese Academy of Sciences, the energy consumption of robots mainly comes from mechanical movement, especially the lifting in the vertical direction and the rapid acceleration movements.

For example, when a robot performs a backflip, it may appear effortless, but it actually demands exceptionally high battery performance. The instantaneous discharge rate required can exceed 100 times that of ordinary batteries in daily use.

An insufficient discharge rate affects the robot's performance, while a heavy battery reduces its flexibility, and low capacity limits its practical use. These issues have become significant challenges for robotics companies.

EngineAI Robotics Technology Co., Ltd., located in south China's tech hub Shenzhen, released an impressive robot dance video in March this year. In the video, the company's PM01 robot flawlessly performed the Axe Gang Dance from Stephen Chow's classic film "Kung Fu," capturing the dance's spirit with remarkable accuracy.

Zhang Nan, a hardware engineer at EngineAI, said that ternary lithium batteries are currently widely used in humanoid robots, and several existing products of EngineAI robots are also equipped with such batteries.

However, such lithium batteries have poor performance in thermal stability. With the development of humanoid robots, solid-state batteries with higher energy density, smaller size and better safety may be the future. "EngineAI is currently in contact with solid-state battery manufacturers for preliminary research," Zhang said.

X Square Robot also faces similar challenges. Wang Qian, founder of the company, said that the company's goal is to have robots take over simple and tedious physical tasks, from electronic assembly work in factories and restaurant service to everyday household chores, making general-purpose robots an indispensable part of people's lives.

The batteries currently used by X Square Robot include ternary lithium batteries and lithium iron phosphate batteries. Their common problem is the low energy density, which affects the overall endurance of the robots. For robots to enter homes and other future application scenarios with high activity levels, they need batteries with higher energy density and, most importantly, maximum safety, Wang explained.

This year's government work report outlined plans to develop future industries like embodied intelligence, highlighting the humanoid robot sector as a key focus. According to the Chinese Institute of Electronics, by 2030, the market size of China's humanoid robots is expected to reach about 870 billion yuan (about 121 billion U.S. dollars).

The swift response has come from tech companies, which are becoming the driving force behind innovation in the country. Some battery manufacturers have recognized this emerging demand and have already partnered with humanoid robot companies for research and development.

For instance, in June, battery giant CATL invested in Beijing-based Galbot, aiming to develop batteries for humanoid robots and to introduce robots into its production lines to achieve factory production automation.

BTR New Material Group, a Shenzhen-based battery supplier, in May launched the FLEX semi-solid and GUARD all-solid-state batteries tailored for humanoid robots. The company has achieved a balance between high performance and lightweight design through two major strategies: material innovation and structural optimization.

For instance, the FLEX series' high-nickel ternary cathodes use molecular-level in-situ coating technology, which can effectively increase the energy density. The GUARD series uses a lithium-rich manganese-based cathode and a lithium metal anode design, which significantly increases the energy density of the individual cell.

According to Li Zikun, director of the company's research institute, the mainstream ternary lithium batteries have shortcomings in terms of energy density, safety and stability, and high-rate discharge performance for humanoid robots. Solid-state batteries can better meet these needs.

Li believes that batteries for future humanoid robots should meet three key requirements: a balance between high energy density and safety, optimized fast charging and discharging efficiency, and stability and reliability under special working conditions.

The all-solid-state battery eliminates the risk of leakage and fire associated with traditional liquid electrolytes, providing a safety guarantee for use under extreme conditions, he said.

These high-energy-density designs can not only support the long-endurance needs of humanoid robots, but are also particularly suitable for increasing the payload in special application scenarios such as aerospace, Li added.

Xinhua